-

130.095Leeson Miscellaneous

130.095Leeson Miscellaneous Item Number130.095MFG Item Number130.095-LEESProduct DescriptionMOTOR BRUSHAvailabilityOrder by 5:00 PM ET and your package will ship the same day.

Item Number130.095MFG Item Number130.095-LEESProduct DescriptionMOTOR BRUSHAvailabilityOrder by 5:00 PM ET and your package will ship the same day. -

M1900030.21Leeson Miscellaneous

M1900030.21Leeson Miscellaneous Item NumberM1900030.21MFG Item NumberM1900030.21Product DescriptionMotor Brush, IndividualAvailabilityOrder by 5:00 PM ET and your package will ship the same day.

Item NumberM1900030.21MFG Item NumberM1900030.21Product DescriptionMotor Brush, IndividualAvailabilityOrder by 5:00 PM ET and your package will ship the same day. -

900007.01Leeson Miscellaneous

900007.01Leeson Miscellaneous Item Number900007.01MFG Item Number900007.01Product DescriptionSpringAvailabilityOrder by 5:00 PM ET and your package will ship the same day.

Item Number900007.01MFG Item Number900007.01Product DescriptionSpringAvailabilityOrder by 5:00 PM ET and your package will ship the same day. -

900163.11Leeson Miscellaneous

900163.11Leeson Miscellaneous Item Number900163.11MFG Item Number900163.11Product DescriptionMotor Brush, IndividualAvailabilityOrder by 5:00 PM ET and your package will ship the same day.

Item Number900163.11MFG Item Number900163.11Product DescriptionMotor Brush, IndividualAvailabilityOrder by 5:00 PM ET and your package will ship the same day. -

900007.02Leeson Miscellaneous

900007.02Leeson Miscellaneous Item Number900007.02MFG Item Number900007.02Product DescriptionSpring for Brush, 900015.03/ 3/8in.AvailabilityOrder by 5:00 PM ET and your package will ship the same day.

Item Number900007.02MFG Item Number900007.02Product DescriptionSpring for Brush, 900015.03/ 3/8in.AvailabilityOrder by 5:00 PM ET and your package will ship the same day. -

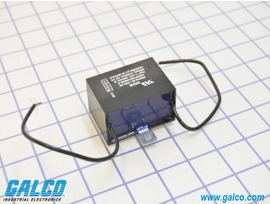

003042.05Leeson Miscellaneous

003042.05Leeson Miscellaneous Item Number003042.05MFG Item Number003042.05Product DescriptionCapacitor, 15ufd, 300VAvailabilityOrder by 5:00 PM ET and your package will ship the same day.

Item Number003042.05MFG Item Number003042.05Product DescriptionCapacitor, 15ufd, 300VAvailabilityOrder by 5:00 PM ET and your package will ship the same day. -

174311.00Leeson Drives

174311.00Leeson Drives Item Number174311.00MFG Item Number174311.00Product DescriptionDC SCR CONTROL.OPENAvailabilityOrder by 5:00 PM ET and your package will ship the same day.

Item Number174311.00MFG Item Number174311.00Product DescriptionDC SCR CONTROL.OPENAvailabilityOrder by 5:00 PM ET and your package will ship the same day. -

900011.01Leeson Miscellaneous

900011.01Leeson Miscellaneous Item Number900011.01MFG Item Number900011.01Product DescriptionBrush ClipAvailabilityOrder by 5:00 PM ET and your package will ship the same day.

Item Number900011.01MFG Item Number900011.01Product DescriptionBrush ClipAvailabilityOrder by 5:00 PM ET and your package will ship the same day. -

900015.18Leeson Miscellaneous

900015.18Leeson Miscellaneous Item Number900015.18MFG Item Number900015.18-LEESProduct DescriptionMotor BrushAvailabilityOrder by 5:00 PM ET and your package will ship the same day.

Item Number900015.18MFG Item Number900015.18-LEESProduct DescriptionMotor BrushAvailabilityOrder by 5:00 PM ET and your package will ship the same day. -

M1120046.00Leeson Motors, DC Motor Series

M1120046.00Leeson Motors, DC Motor Series Item NumberM1120046.00MFG Item NumberM1120046.00SeriesDC MotorProduct Description..1/6HP-1/3HP..1800RPM - 3900RPM.31.TESpecifications

Item NumberM1120046.00MFG Item NumberM1120046.00SeriesDC MotorProduct Description..1/6HP-1/3HP..1800RPM - 3900RPM.31.TESpecificationsSpecifications Max RPM 3,900 RPM Armature Voltage 24 V Armature Current 14 A Enclosure Type Totally Enclosed Non-Ventilated Mounting Type Square Flange Model Number M31D17NZ26 AvailabilityOrder by 5:00 PM ET and your package will ship the same day.

Search