-

RMEH4BLPanduit Printers

RMEH4BLPanduit Printers Item NumberRMEH4BLMFG Item NumberRMEH4BLProduct DescriptionRMEH4BL Thermal Transfer Ribbon, Wax/ResAvailabilityOrder by 5:00 PM ET and your package will ship the same day.

Item NumberRMEH4BLMFG Item NumberRMEH4BLProduct DescriptionRMEH4BL Thermal Transfer Ribbon, Wax/ResAvailabilityOrder by 5:00 PM ET and your package will ship the same day. -

PSL-MCBNTPanduit Lockout/Tagout

PSL-MCBNTPanduit Lockout/Tagout Item NumberPSL-MCBNTMFG Item NumberPSL-MCBNTProduct DescriptionPSL-MCBNT Circuit Breaker Lockout no tooAvailability

Item NumberPSL-MCBNTMFG Item NumberPSL-MCBNTProduct DescriptionPSL-MCBNT Circuit Breaker Lockout no tooAvailability -

PSL-CBILNTPanduit Lockout/Tagout

PSL-CBILNTPanduit Lockout/Tagout Item NumberPSL-CBILNTMFG Item NumberPSL-CBILNTProduct DescriptionPSL-CBILNT Circuit Breaker Lockout I-LinAvailabilityOrder by 5:00 PM ET and your package will ship the same day.

Item NumberPSL-CBILNTMFG Item NumberPSL-CBILNTProduct DescriptionPSL-CBILNT Circuit Breaker Lockout I-LinAvailabilityOrder by 5:00 PM ET and your package will ship the same day. -

PSL-CBNTPanduit Lockout/Tagout

PSL-CBNTPanduit Lockout/Tagout Item NumberPSL-CBNTMFG Item NumberPSL-CBNTProduct DescriptionPSL-CBNT Circuit Breaker Lockout no toolAvailabilityOrder by 5:00 PM ET and your package will ship the same day.

Item NumberPSL-CBNTMFG Item NumberPSL-CBNTProduct DescriptionPSL-CBNT Circuit Breaker Lockout no toolAvailabilityOrder by 5:00 PM ET and your package will ship the same day. -

S100X125VACPanduit Labels, P1 Self-Laminating Label Cassettes Series

S100X125VACPanduit Labels, P1 Self-Laminating Label Cassettes Series Item NumberS100X125VACMFG Item NumberS100X125VACSeriesP1 Self-Laminating Label CassettesProduct DescriptionP1 S100X125VAC Self-Lam, Vinyl, White,Specifications

Item NumberS100X125VACMFG Item NumberS100X125VACSeriesP1 Self-Laminating Label CassettesProduct DescriptionP1 S100X125VAC Self-Lam, Vinyl, White,SpecificationsSpecifications Application Cable & Wire Marking Label Height 1 " Label Width 1.25 " Material Description Self-Laminating Panel Application Wire & Cable Marking Recommended Printer(s) PanTher LS8E/LS8EQ Unit Of Measure Cartridge AvailabilityOrder by 5:00 PM ET and your package will ship the same day. -

P10-56R-LPanduit Terminals, Pan-Term Terminals Series

P10-56R-LPanduit Terminals, Pan-Term Terminals Series Item NumberP10-56R-LMFG Item NumberP10-56R-LSeriesPan-Term TerminalsProduct DescriptionPan-Term P10-56R-L Ring TerminalSpecifications

Item NumberP10-56R-LMFG Item NumberP10-56R-LSeriesPan-Term TerminalsProduct DescriptionPan-Term P10-56R-L Ring TerminalSpecificationsSpecifications Terminal Type Ring Wire Size 12-10 AWG Package Quantity 50 Volts 2,000 V Stud Size 5/16 " Max Temp 302 °F RoHS Compliant Yes AvailabilityOrder by 5:00 PM ET and your package will ship the same day. -

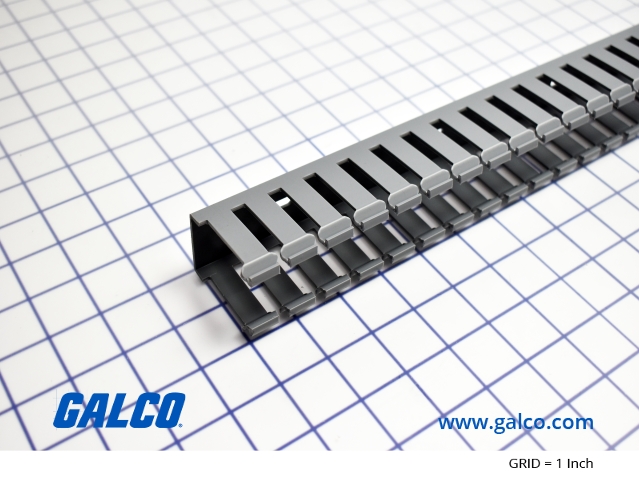

G1X2LG6Panduit Wire Duct, Panduct Type G Series

G1X2LG6Panduit Wire Duct, Panduct Type G Series Item NumberG1X2LG6MFG Item NumberG1X2LG6SeriesPanduct Type GProduct DescriptionPanduct G1X2LG6 Base Wiring DuctSpecifications

Item NumberG1X2LG6MFG Item NumberG1X2LG6SeriesPanduct Type GProduct DescriptionPanduct G1X2LG6 Base Wiring DuctSpecificationsSpecifications Cover Incl. No Color Gray Nominal Height 2 " Nominal Width 1.5 " AvailabilityOrder by 5:00 PM ET and your package will ship the same day. -

EDV18-87MB-QPanduit Terminals

EDV18-87MB-QPanduit Terminals Item NumberEDV18-87MB-QMFG Item NumberEDV18-87MB-QProduct DescriptionStrongHold EDV18-87MB-Q Blade TerminalSpecifications

Item NumberEDV18-87MB-QMFG Item NumberEDV18-87MB-QProduct DescriptionStrongHold EDV18-87MB-Q Blade TerminalSpecificationsSpecifications Terminal Type Barrel - Standard Wire Size 22-18 AWG Package Quantity 25 Volts 600 V Insulation Material Vinyl Color Red Max Temp 221 °F RoHS Compliant No Availability -

C1LG6Panduit Wire Duct

C1LG6Panduit Wire Duct Item NumberC1LG6MFG Item NumberC1LG6Product DescriptionPanduct C1LG6 Flush Duct CoverAvailabilityOrder by 5:00 PM ET and your package will ship the same day.

Item NumberC1LG6MFG Item NumberC1LG6Product DescriptionPanduct C1LG6 Flush Duct CoverAvailabilityOrder by 5:00 PM ET and your package will ship the same day. -

F1X3LG6Panduit Wire Duct, Panduct Type F Series

F1X3LG6Panduit Wire Duct, Panduct Type F Series Item NumberF1X3LG6MFG Item NumberF1X3LG6SeriesPanduct Type FProduct DescriptionPanduct F1X3LG6 Base Wiring DuctSpecifications

Item NumberF1X3LG6MFG Item NumberF1X3LG6SeriesPanduct Type FProduct DescriptionPanduct F1X3LG6 Base Wiring DuctSpecificationsSpecifications Cover Incl. No Color Gray Nominal Height 3 " Nominal Width 1.25 " AvailabilityOrder by 5:00 PM ET and your package will ship the same day.

Search