-

P1160100000Partlow Process Controllers, 1160 Series

P1160100000Partlow Process Controllers, 1160 Series Item NumberP1160100000MFG Item NumberP1160100000Series1160Product DescriptionProcess Controller, 1/16DIN, 100-240Specifications

Item NumberP1160100000MFG Item NumberP1160100000Series1160Product DescriptionProcess Controller, 1/16DIN, 100-240SpecificationsSpecifications Power Supply 100-240 VAC Output Type Relay Number of Outputs 1 Case Size 1/16 DIN AvailabilityOrder by 5:00 PM ET and your package will ship the same day. -

P1161100000Partlow Process Controllers, 1161 Series

P1161100000Partlow Process Controllers, 1161 Series Item NumberP1161100000MFG Item NumberP1161100000Series1161Product DescriptionLimit ControllerSpecifications

Item NumberP1161100000MFG Item NumberP1161100000Series1161Product DescriptionLimit ControllerSpecificationsSpecifications Power Supply 100-240 VAC Output Type Relay Number of Outputs 1 Case Size 1/16 DIN AvailabilityOrder by 5:00 PM ET and your package will ship the same day. -

60500401Partlow Miscellaneous

60500401Partlow Miscellaneous Item Number60500401MFG Item Number60500401Product DescriptionGREEN CARTRIDGE PENAvailabilityOrder by 5:00 PM ET and your package will ship the same day.

Item Number60500401MFG Item Number60500401Product DescriptionGREEN CARTRIDGE PENAvailabilityOrder by 5:00 PM ET and your package will ship the same day. -

60500402Partlow Miscellaneous

60500402Partlow Miscellaneous Item Number60500402MFG Item Number60500402Product DescriptionPEN CARTRIDGE REDAvailabilityOrder by 5:00 PM ET and your package will ship the same day.

Item Number60500402MFG Item Number60500402Product DescriptionPEN CARTRIDGE REDAvailabilityOrder by 5:00 PM ET and your package will ship the same day. -

BM118500Partlow Miscellaneous

BM118500Partlow Miscellaneous Item NumberBM118500MFG Item NumberBM118500Product DescriptionBM1920001 115VAvailabilityOrder by 5:00 PM ET and your package will ship the same day.

Item NumberBM118500MFG Item NumberBM118500Product DescriptionBM1920001 115VAvailabilityOrder by 5:00 PM ET and your package will ship the same day. -

P1800200000Partlow Process Controllers, 1800 Series

P1800200000Partlow Process Controllers, 1800 Series Item NumberP1800200000MFG Item NumberP1800200000Series1800Product DescriptionPlus Series 1/8 DIN ControllerSpecifications

Item NumberP1800200000MFG Item NumberP1800200000Series1800Product DescriptionPlus Series 1/8 DIN ControllerSpecificationsSpecifications Power Supply 100-240 VAC Output Type Solid State AC Number of Outputs 1 Case Size 1/8 DIN AvailabilityOrder by 5:00 PM ET and your package will ship the same day. -

P1161110800Partlow Process Controllers, 1611 Series

P1161110800Partlow Process Controllers, 1611 Series Item NumberP1161110800MFG Item NumberP1161110800Series1611Product DescriptionPlus Series Limit Device, 1/16 DINSpecifications

Item NumberP1161110800MFG Item NumberP1161110800Series1611Product DescriptionPlus Series Limit Device, 1/16 DINSpecificationsSpecifications Power Supply 100-240 VAC Output Type Relay Number of Outputs 2 Case Size 1/16 DIN AvailabilityOrder by 5:00 PM ET and your package will ship the same day. -

64431701Partlow Miscellaneous

64431701Partlow Miscellaneous Item Number64431701MFG Item Number64431701Product DescriptionCOMMUNICATION KITAvailabilityOrder by 5:00 PM ET and your package will ship the same day.

Item Number64431701MFG Item Number64431701Product DescriptionCOMMUNICATION KITAvailabilityOrder by 5:00 PM ET and your package will ship the same day. -

64414701Partlow Miscellaneous

64414701Partlow Miscellaneous Item Number64414701MFG Item Number64414701Product DescriptionKEYPAD, MODEL 7110AvailabilityOrder by 5:00 PM ET and your package will ship the same day.

Item Number64414701MFG Item Number64414701Product DescriptionKEYPAD, MODEL 7110AvailabilityOrder by 5:00 PM ET and your package will ship the same day. -

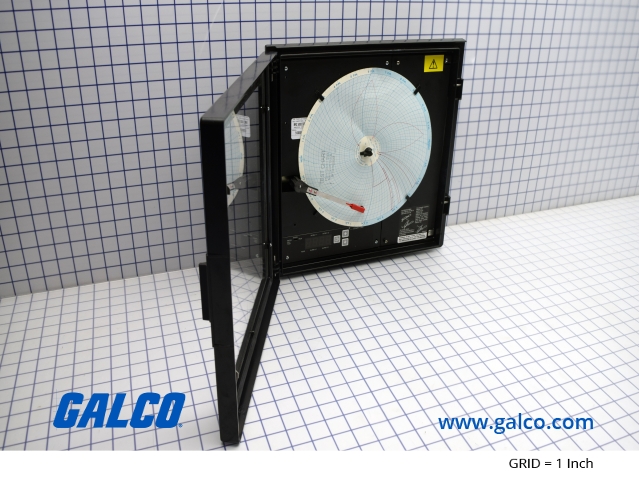

51000015Partlow Chart Recorders, MRC 5000 Series

51000015Partlow Chart Recorders, MRC 5000 Series Item Number51000015MFG Item Number51000015SeriesMRC 5000Product DescriptionMRC5000 1 PEN RCD/---/STD VSpecifications

Item Number51000015MFG Item Number51000015SeriesMRC 5000Product DescriptionMRC5000 1 PEN RCD/---/STD VSpecificationsSpecifications Type Paper Number of Pens 1 Communications None Operating Voltage 100-240 VAC Enclosure Rating NEMA 3 Door Lock No Sealed Conduit No AvailabilityOrder by 5:00 PM ET and your package will ship the same day.

Search