-

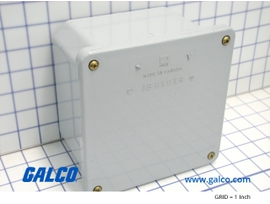

F963Stahlin Enclosures, CF Series

F963Stahlin Enclosures, CF Series Item NumberF963MFG Item NumberF963SeriesCFProduct DescriptionEnclosure, 9.87in.Hx6.63in.Wx3.19in.D, NSpecifications

Item NumberF963MFG Item NumberF963SeriesCFProduct DescriptionEnclosure, 9.87in.Hx6.63in.Wx3.19in.D, NSpecificationsSpecifications Composition Non-Metallic Number of Doors 1 Cover Design Lift-Off Cover Window/Clear Cover No Latching Mechanism Screws Options Included Gasketed Cover Panel Included No Nominal Height 9 " Nominal Width 6 " Nominal Depth 3 " AvailabilityOrder by 5:00 PM ET and your package will ship the same day. -

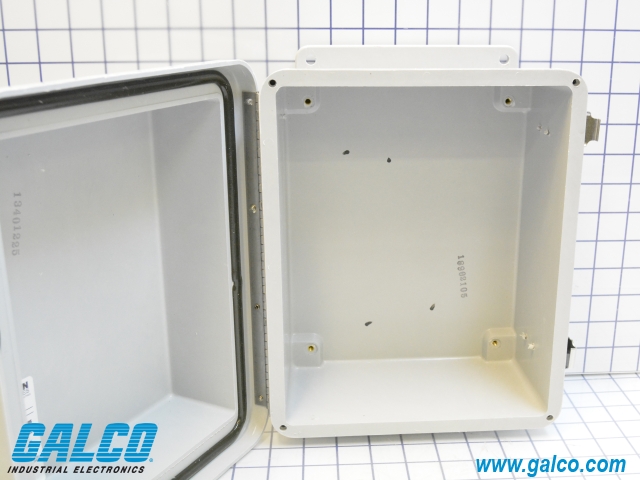

J1008HPLStahlin Enclosures, J Series

J1008HPLStahlin Enclosures, J Series Item NumberJ1008HPLMFG Item NumberJ1008HPLSeriesJProduct DescriptionEnclosure, 11.63in.Hx9.37in.Wx5.08in.D,Specifications

Item NumberJ1008HPLMFG Item NumberJ1008HPLSeriesJProduct DescriptionEnclosure, 11.63in.Hx9.37in.Wx5.08in.D,SpecificationsSpecifications Composition Non-Metallic Number of Doors 1 Cover Design Hinged Window/Clear Cover No Latching Mechanism Padlockable Latch Options Included Gasketed Cover Panel Included No Nominal Height 10 " Nominal Width 8 " Nominal Depth 4 " AvailabilityOrder by 5:00 PM ET and your package will ship the same day. -

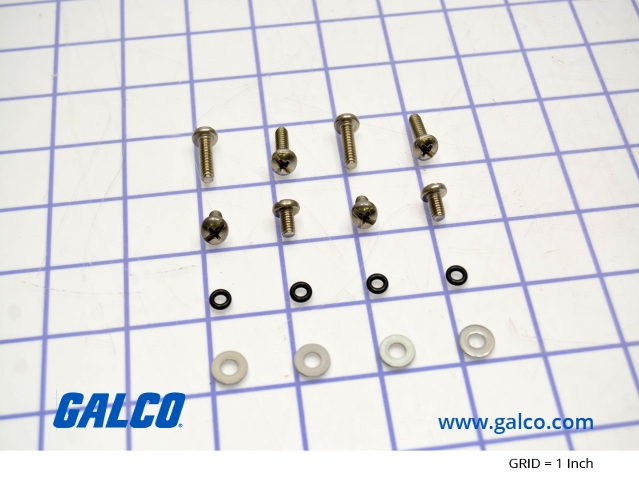

CF5PB22Stahlin Enclosures, Pushbutton Series

CF5PB22Stahlin Enclosures, Pushbutton Series Item NumberCF5PB22MFG Item NumberCF5PB22SeriesPushbuttonProduct DescriptionPushbutton Enclosure, 5-Hole, 22mm,Specifications

Item NumberCF5PB22MFG Item NumberCF5PB22SeriesPushbuttonProduct DescriptionPushbutton Enclosure, 5-Hole, 22mm,SpecificationsSpecifications Composition Non-Metallic Number of Holes 5 Hole Size (mm) 22 mm Cover Design Lift-Off Cover Latching Mechanism Screws AvailabilityOrder by 5:00 PM ET and your package will ship the same day. -

CF1PBStahlin Enclosures, Pushbutton Series

CF1PBStahlin Enclosures, Pushbutton Series Item NumberCF1PBMFG Item NumberCF1PBSeriesPushbuttonProduct DescriptionPushbutton Enclosure, 1-Hole, 30mm,Specifications

Item NumberCF1PBMFG Item NumberCF1PBSeriesPushbuttonProduct DescriptionPushbutton Enclosure, 1-Hole, 30mm,SpecificationsSpecifications Composition Non-Metallic Number of Holes 1 Hole Size (mm) 30 mm Cover Design Lift-Off Cover Latching Mechanism Screws AvailabilityOrder by 5:00 PM ET and your package will ship the same day. -

J664PVCStahlin Enclosures, NewSentry Series

J664PVCStahlin Enclosures, NewSentry Series Item NumberJ664PVCMFG Item NumberJ664PVCSeriesNewSentryProduct DescriptionEnclosure, 6.85in.Hx6.85in.Wx4.57in.D,Specifications

Item NumberJ664PVCMFG Item NumberJ664PVCSeriesNewSentryProduct DescriptionEnclosure, 6.85in.Hx6.85in.Wx4.57in.D,SpecificationsSpecifications Composition Non-Metallic Number of Doors 1 Cover Design Lift-Off Cover Window/Clear Cover No Latching Mechanism Screws Options Included Gasketed Cover Panel Included No Nominal Height 6 " Nominal Width 6 " Nominal Depth 4 " AvailabilityOrder by 5:00 PM ET and your package will ship the same day. -

BP66ALStahlin Enclosures

BP66ALStahlin Enclosures Item NumberBP66ALMFG Item NumberBP66ALProduct DescriptionAluminum Back PanelSpecifications

Item NumberBP66ALMFG Item NumberBP66ALProduct DescriptionAluminum Back PanelSpecificationsSpecifications Composition Metallic Perforated No Kit with Hardware No Nominal Height 6 " Nominal Width 6 " AvailabilityOrder by 5:00 PM ET and your package will ship the same day. -

J806HPLStahlin Enclosures, J Series

J806HPLStahlin Enclosures, J Series Item NumberJ806HPLMFG Item NumberJ806HPLSeriesJProduct DescriptionEnclosure, 9.63in.Hx7.52in.Wx4.7in.D, N4Specifications

Item NumberJ806HPLMFG Item NumberJ806HPLSeriesJProduct DescriptionEnclosure, 9.63in.Hx7.52in.Wx4.7in.D, N4SpecificationsSpecifications Composition Non-Metallic Number of Doors 1 Cover Design Hinged Window/Clear Cover No Latching Mechanism Padlockable Latch Options Included Gasketed Cover Panel Included No Nominal Height 8 " Nominal Width 6 " Nominal Depth 4 " AvailabilityOrder by 5:00 PM ET and your package will ship the same day. -

BP86ALStahlin Enclosures

BP86ALStahlin Enclosures Item NumberBP86ALMFG Item NumberBP86ALProduct DescriptionAluminum Back PanelSpecifications

Item NumberBP86ALMFG Item NumberBP86ALProduct DescriptionAluminum Back PanelSpecificationsSpecifications Composition Metallic Perforated No Kit with Hardware No Nominal Height 8 " Nominal Width 6 " AvailabilityOrder by 5:00 PM ET and your package will ship the same day. -

J1816HPLStahlin Enclosures, J Series

J1816HPLStahlin Enclosures, J Series Item NumberJ1816HPLMFG Item NumberJ1816HPLSeriesJProduct DescriptionEnclosure, 19.63in.Hx17.61in.Wx8.81in.D,Specifications

Item NumberJ1816HPLMFG Item NumberJ1816HPLSeriesJProduct DescriptionEnclosure, 19.63in.Hx17.61in.Wx8.81in.D,SpecificationsSpecifications Composition Non-Metallic Number of Doors 1 Cover Design Hinged Window/Clear Cover No Latching Mechanism Padlockable Latch Options Included Gasketed Cover Panel Included No Nominal Height 18 " Nominal Width 16 " Nominal Depth 8 " AvailabilityOrder by 5:00 PM ET and your package will ship the same day. -

J808HPLStahlin Enclosures, J Series

J808HPLStahlin Enclosures, J Series Item NumberJ808HPLMFG Item NumberJ808HPLSeriesJProduct DescriptionEnclosure, 9.56in.Hx9.38in.Wx4.87in.D, NSpecifications

Item NumberJ808HPLMFG Item NumberJ808HPLSeriesJProduct DescriptionEnclosure, 9.56in.Hx9.38in.Wx4.87in.D, NSpecificationsSpecifications Composition Non-Metallic Number of Doors 1 Cover Design Hinged Window/Clear Cover No Latching Mechanism Padlockable Latch Options Included Gasketed Cover Panel Included No Nominal Height 8 " Nominal Width 8 " Nominal Depth 4 " AvailabilityOrder by 5:00 PM ET and your package will ship the same day.

Search