-

E1015-8306Cooper Connectors, J Series

E1015-8306Cooper Connectors, J Series Item NumberE1015-8306MFG Item NumberE1015-8306SeriesJProduct DescriptionCAM-LOK, Male Plug, 600V, 150A, Black,Specifications

Item NumberE1015-8306MFG Item NumberE1015-8306SeriesJProduct DescriptionCAM-LOK, Male Plug, 600V, 150A, Black,SpecificationsSpecifications Connection Type Plug Connection Description Male Current Rating 150 A Voltage 600 VAC Cable Size #8-#4 Cable Attachment Method Single Set Screw Insulator Material Thermoplastic Elastomer (TPE) Connector Color Black NEMA Rating NEMA 3R Interlock Switch No AvailabilityOrder by 5:00 PM ET and your package will ship the same day. -

E1015-8308Cooper Connectors, J Series

E1015-8308Cooper Connectors, J Series Item NumberE1015-8308MFG Item NumberE1015-8308SeriesJProduct DescriptionCAM-LOK, Male Plug, 600V, 150A, Red,Specifications

Item NumberE1015-8308MFG Item NumberE1015-8308SeriesJProduct DescriptionCAM-LOK, Male Plug, 600V, 150A, Red,SpecificationsSpecifications Connection Type Plug Connection Description Male Current Rating 150 A Voltage 600 VAC Cable Size #8-#4 Cable Attachment Method Single Set Screw Insulator Material Thermoplastic Elastomer (TPE) Connector Color Red NEMA Rating NEMA 3R Interlock Switch No AvailabilityOrder by 5:00 PM ET and your package will ship the same day. -

DMS3100A22-14S-FFujikura, Formerly DDK Connectors, DMS-F SeriesItem NumberDMS3100A22-14S-FMFG Item NumberDMS3100A22-14S-FSeriesDMS-FProduct DescriptionConnectorSpecifications

DMS3100A22-14S-FFujikura, Formerly DDK Connectors, DMS-F SeriesItem NumberDMS3100A22-14S-FMFG Item NumberDMS3100A22-14S-FSeriesDMS-FProduct DescriptionConnectorSpecificationsSpecifications No. of Contacts 19 Contact Material Silver Plated Wire Sizes 19-#16 Service Code A Length 2.13 " Diameter 1.37 " AvailabilityOrder by 5:00 PM ET and your package will ship the same day. -

DMS3106A22-14P-FFujikura, Formerly DDK Connectors, DMS-F SeriesItem NumberDMS3106A22-14P-FMFG Item NumberDMS3106A22-14P-FSeriesDMS-FProduct DescriptionConnectorSpecifications

DMS3106A22-14P-FFujikura, Formerly DDK Connectors, DMS-F SeriesItem NumberDMS3106A22-14P-FMFG Item NumberDMS3106A22-14P-FSeriesDMS-FProduct DescriptionConnectorSpecificationsSpecifications No. of Contacts 19 Contact Material Silver Plated Wire Sizes 19-#16 Service Code A Length 2.12 " Diameter 1.37 " AvailabilityOrder by 5:00 PM ET and your package will ship the same day. -

E1016-8369Cooper Connectors, J Series

E1016-8369Cooper Connectors, J Series Item NumberE1016-8369MFG Item NumberE1016-8369SeriesJProduct DescriptionCAM-LOK, Male Plug, 600V, 400A, Brown,Specifications

Item NumberE1016-8369MFG Item NumberE1016-8369SeriesJProduct DescriptionCAM-LOK, Male Plug, 600V, 400A, Brown,SpecificationsSpecifications Connection Type Plug Connection Description Male Current Rating 400 A Voltage 600 VAC Cable Size 2/0-4/0 Cable Attachment Method Double Set Screw Insulator Material Thermoplastic Elastomer (TPE) Connector Color Brown NEMA Rating NEMA 3R Interlock Switch No AvailabilityOrder by 5:00 PM ET and your package will ship the same day. -

CLS40MB-AAdvanced Devices (Marinco) Connectors, CLS SeriesItem NumberCLS40MB-AMFG Item NumberCLS40MB-ASeriesCLSProduct DescriptionCAM LOCK, 4/0- 2/0 AWG, MALE ENDSpecifications

CLS40MB-AAdvanced Devices (Marinco) Connectors, CLS SeriesItem NumberCLS40MB-AMFG Item NumberCLS40MB-ASeriesCLSProduct DescriptionCAM LOCK, 4/0- 2/0 AWG, MALE ENDSpecificationsSpecifications Connection Type Plug Connection Description Male Current Rating 400 A Voltage 600 VAC Cable Size 2/0-4/0 Cable Attachment Method Double Set Screw Insulator Material Thermoplastic Elastomer (TPE) Connector Color Black Interlock Switch No AvailabilityOrder by 5:00 PM ET and your package will ship the same day. -

CLS40MB-CAdvanced Devices (Marinco) Connectors, CLS SeriesItem NumberCLS40MB-CMFG Item NumberCLS40MB-CSeriesCLSProduct DescriptionCAM LOCK, 4/0- 2/0 AWG, MALE ENDSpecifications

CLS40MB-CAdvanced Devices (Marinco) Connectors, CLS SeriesItem NumberCLS40MB-CMFG Item NumberCLS40MB-CSeriesCLSProduct DescriptionCAM LOCK, 4/0- 2/0 AWG, MALE ENDSpecificationsSpecifications Connection Type Plug Connection Description Male Current Rating 400 A Voltage 600 VAC Cable Size 2/0-4/0 Cable Attachment Method Double Set Screw Insulator Material Thermoplastic Elastomer (TPE) Connector Color Red Interlock Switch No AvailabilityOrder by 5:00 PM ET and your package will ship the same day. -

CLS40MB-EAdvanced Devices (Marinco) Connectors, CLS SeriesItem NumberCLS40MB-EMFG Item NumberCLS40MB-ESeriesCLSProduct DescriptionCAM LOCK, 4/0- 2/0 AWG, MALE ENDSpecifications

CLS40MB-EAdvanced Devices (Marinco) Connectors, CLS SeriesItem NumberCLS40MB-EMFG Item NumberCLS40MB-ESeriesCLSProduct DescriptionCAM LOCK, 4/0- 2/0 AWG, MALE ENDSpecificationsSpecifications Connection Type Plug Connection Description Male Current Rating 400 A Voltage 600 VAC Cable Size 2/0-4/0 Cable Attachment Method Double Set Screw Insulator Material Thermoplastic Elastomer (TPE) Connector Color Green Interlock Switch No AvailabilityOrder by 5:00 PM ET and your package will ship the same day. -

CLS40MB-DAdvanced Devices (Marinco) Connectors, CLS SeriesItem NumberCLS40MB-DMFG Item NumberCLS40MB-DSeriesCLSProduct DescriptionCAM LOCK, 4/0- 2/0 AWG, MALE ENDSpecifications

CLS40MB-DAdvanced Devices (Marinco) Connectors, CLS SeriesItem NumberCLS40MB-DMFG Item NumberCLS40MB-DSeriesCLSProduct DescriptionCAM LOCK, 4/0- 2/0 AWG, MALE ENDSpecificationsSpecifications Connection Type Plug Connection Description Male Current Rating 400 A Voltage 600 VAC Cable Size 2/0-4/0 Cable Attachment Method Double Set Screw Insulator Material Thermoplastic Elastomer (TPE) Connector Color Blue Interlock Switch No AvailabilityOrder by 5:00 PM ET and your package will ship the same day. -

CLS40FB-AAdvanced Devices (Marinco) Connectors, CLS SeriesItem NumberCLS40FB-AMFG Item NumberCLS40FB-ASeriesCLSProduct DescriptionCAM LOCK, 4/0- 2/0 AWG, FEMALE ENDSpecifications

CLS40FB-AAdvanced Devices (Marinco) Connectors, CLS SeriesItem NumberCLS40FB-AMFG Item NumberCLS40FB-ASeriesCLSProduct DescriptionCAM LOCK, 4/0- 2/0 AWG, FEMALE ENDSpecificationsSpecifications Connection Type Plug Connection Description Female Current Rating 400 A Voltage 600 VAC Cable Size 2/0-4/0 Cable Attachment Method Double Set Screw Insulator Material Thermoplastic Elastomer (TPE) Connector Color Black Interlock Switch No AvailabilityOrder by 5:00 PM ET and your package will ship the same day.

Search

Connectors

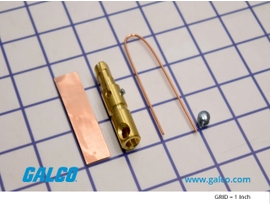

Electrical connectors are devices used to join electrical terminations and complete a working circuit. Connectors work in pairs: plugs (male) and jacks (female). Hundreds of connector types exist for power, signal, and control applications.

A wide variety of characteristics help determine the use case for a connector. Different connectors have different pinouts, contact resistance, insulation, sizes, ruggedness, resistance to external hazards, and more. Different physical construction styles exist to easily differentiate one type of connector from another. Connector pairs share most if not all characteristics, and can’t work with a plug or jack of another type.

Common connectors include cam-style, circular, coaxial, pin and sleeve, rectangular, straight blade, and mechanical for splice and reducing. Many include twist locks and are keyed to prevent disconnection and ensure the correct plug joins with the correct receptacle.

A wide variety of characteristics help determine the use case for a connector. Different connectors have different pinouts, contact resistance, insulation, sizes, ruggedness, resistance to external hazards, and more. Different physical construction styles exist to easily differentiate one type of connector from another. Connector pairs share most if not all characteristics, and can’t work with a plug or jack of another type.

Common connectors include cam-style, circular, coaxial, pin and sleeve, rectangular, straight blade, and mechanical for splice and reducing. Many include twist locks and are keyed to prevent disconnection and ensure the correct plug joins with the correct receptacle.