-

ML6984A4000/UHoneywell HVAC Valves, ML6984 Series

ML6984A4000/UHoneywell HVAC Valves, ML6984 Series Item NumberML6984A4000/UMFG Item NumberML6984A4000/USeriesML6984Product DescriptionVALVE ACTUATOR DIGITAL INTERFACESpecifications

Item NumberML6984A4000/UMFG Item NumberML6984A4000/USeriesML6984Product DescriptionVALVE ACTUATOR DIGITAL INTERFACESpecificationsSpecifications Run Time 63 s Media Temperature 300 °F Manual Operation No AvailabilityOrder by 5:00 PM ET and your package will ship the same day. -

AG13A02ASchneider HVAC Valves

AG13A02ASchneider HVAC Valves Item NumberAG13A02AMFG Item Number132879Product DescriptionActuator, Electric, 2Pos, SR, 24Specifications

Item NumberAG13A02AMFG Item Number132879Product DescriptionActuator, Electric, 2Pos, SR, 24SpecificationsSpecifications Control Signal Two Position Supply Voltage 24 VAC Media Temperature 32-200 °F Manual Operation Yes AvailabilityOrder by 5:00 PM ET and your package will ship the same day. -

VA-4233-AGA-2Johnson Controls HVAC Valves, VA-4233 SeriesItem NumberVA-4233-AGA-2MFG Item NumberVA-4233-AGA-2SeriesVA-4233Product DescriptionUva Linear Actr. Ccw; ActuatorSpecifications

VA-4233-AGA-2Johnson Controls HVAC Valves, VA-4233 SeriesItem NumberVA-4233-AGA-2MFG Item NumberVA-4233-AGA-2SeriesVA-4233Product DescriptionUva Linear Actr. Ccw; ActuatorSpecificationsSpecifications Control Signal Floating Run Time 76 s Media Temperature 35-250 °F Manual Operation Yes AvailabilityOrder by 5:00 PM ET and your package will ship the same day. -

PNV-102-1Schneider HVAC Valves, PNV Series

PNV-102-1Schneider HVAC Valves, PNV Series Item NumberPNV-102-1MFG Item Number108690SeriesPNVProduct DescriptionDiaphragm AL-161-4, MK-2690 andSpecifications

Item NumberPNV-102-1MFG Item Number108690SeriesPNVProduct DescriptionDiaphragm AL-161-4, MK-2690 andSpecificationsSpecifications Stroke 0.5 " AvailabilityOrder by 5:00 PM ET and your package will ship the same day. -

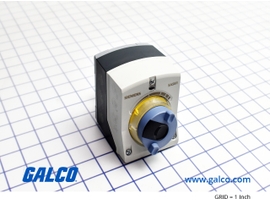

SAX61.03USiemens Building Technologies HVAC Valves, SAX Series

SAX61.03USiemens Building Technologies HVAC Valves, SAX Series Item NumberSAX61.03UMFG Item NumberSAX61.03USeriesSAXProduct DescriptionELEC/MECH ACT, 0-10VDC, 30S, NSRSpecifications

Item NumberSAX61.03UMFG Item NumberSAX61.03USeriesSAXProduct DescriptionELEC/MECH ACT, 0-10VDC, 30S, NSRSpecificationsSpecifications Control Signal Proportional 0-10 VDC Run Time 30 s Media Temperature 266 °F Manual Operation No AvailabilityOrder by 5:00 PM ET and your package will ship the same day. -

SKD62USiemens Building Technologies HVAC Valves, SKD Series

SKD62USiemens Building Technologies HVAC Valves, SKD Series Item NumberSKD62UMFG Item NumberSKD62USeriesSKDProduct DescriptionValve Actuator, 24VAC, 0-10VDC orSpecifications

Item NumberSKD62UMFG Item NumberSKD62USeriesSKDProduct DescriptionValve Actuator, 24VAC, 0-10VDC orSpecificationsSpecifications Supply Voltage 24 VAC Run Time 30 s Media Temperature 14-300 °F Manual Operation Yes AvailabilityOrder by 5:00 PM ET and your package will ship the same day. -

VT2317G13A02ASchneider HVAC Valves, VT2 Series

VT2317G13A02ASchneider HVAC Valves, VT2 Series Item NumberVT2317G13A02AMFG Item Number139244SeriesVT2Product DescriptionValve: 3/4 in, 2W, Zone, SWT, BR,Specifications

Item NumberVT2317G13A02AMFG Item Number139244SeriesVT2Product DescriptionValve: 3/4 in, 2W, Zone, SWT, BR,SpecificationsSpecifications Flow Capacity 7.5 Cv Connection Type Sweat Max Close-Off Pressure 17 psi Max Static Pressure 400 psi Medium Temperature Range 32-200 °F Nominal Supply Voltage 24 VAC AvailabilityOrder by 5:00 PM ET and your package will ship the same day. -

V47AC-6CJohnson Controls HVAC Valves, V47 SeriesItem NumberV47AC-6CMFG Item NumberV47AC-6CSeriesV47Product DescriptionTemp Act Modulating Valve; TempSpecifications

V47AC-6CJohnson Controls HVAC Valves, V47 SeriesItem NumberV47AC-6CMFG Item NumberV47AC-6CSeriesV47Product DescriptionTemp Act Modulating Valve; TempSpecificationsSpecifications Min Opening Point 75 °F Max Opening Point 135 °F AvailabilityOrder by 5:00 PM ET and your package will ship the same day. -

SAS61.03USiemens Building Technologies HVAC Valves

SAS61.03USiemens Building Technologies HVAC Valves Item NumberSAS61.03UMFG Item NumberSAS61.03UProduct DescriptionVALVE ACTUATORSpecifications

Item NumberSAS61.03UMFG Item NumberSAS61.03UProduct DescriptionVALVE ACTUATORSpecificationsSpecifications Manual Operation Yes AvailabilityOrder by 5:00 PM ET and your package will ship the same day. -

599-03079Siemens Building Technologies HVAC Valves, FLOWRITE Series

599-03079Siemens Building Technologies HVAC Valves, FLOWRITE Series Item Number599-03079MFG Item Number599-03079SeriesFLOWRITEProduct Description1 1/2in.N.C., SS, 250, 25.0CV, STEAMSpecifications

Item Number599-03079MFG Item Number599-03079SeriesFLOWRITEProduct Description1 1/2in.N.C., SS, 250, 25.0CV, STEAMSpecificationsSpecifications Flow Capacity 25 Cv Connection Type Threaded Max Close-Off Pressure 50 psi Medium Temperature Range 337 °F AvailabilityOrder by 5:00 PM ET and your package will ship the same day.

Search

HVAC Valves

A valve is a device that regulates the flow of a fluid by opening, closing, or partially obstructing a passageway.

Modern control valves operate on sophisticated automation systems that are based on external input. The valve is used to regulate flow based on previously-determined setpoints or variables, for example. These types of valves require an actuator, which will position the valve accurately depending on its input and setup. Actuators can be electrical, hydraulic, or pneumatic, depending on the application and its environment.

Valves are critical in HVAC applications, and paired with actuators are designed to regulate the flow of both hot and chilled water in HVAC systems. Ball valves are most common for HVAC systems, able to regulate flow in several different directions with just one fitting.

Modern control valves operate on sophisticated automation systems that are based on external input. The valve is used to regulate flow based on previously-determined setpoints or variables, for example. These types of valves require an actuator, which will position the valve accurately depending on its input and setup. Actuators can be electrical, hydraulic, or pneumatic, depending on the application and its environment.

Valves are critical in HVAC applications, and paired with actuators are designed to regulate the flow of both hot and chilled water in HVAC systems. Ball valves are most common for HVAC systems, able to regulate flow in several different directions with just one fitting.