-

47-20448-BKNTE Electronics Shrink Tubing, THIN WALL Series

47-20448-BKNTE Electronics Shrink Tubing, THIN WALL Series Item Number47-20448-BKMFG Item Number47-20448-BKSeriesTHIN WALLProduct DescriptionHeat Shrink, 3/16in.x48in., Black, 2:1,Specifications

Item Number47-20448-BKMFG Item Number47-20448-BKSeriesTHIN WALLProduct DescriptionHeat Shrink, 3/16in.x48in., Black, 2:1,SpecificationsSpecifications Nom. Inner Diameter (in) 3/16 " Piece Length (in) 48 " Color Black Number of Pieces 1 Recovered Diameter 0.094 " Recovered Wall Thickness 0.02 " Adhesive Lining No Recovery Temperature 194 °F Operating Temperature -67-275 °F Availability -

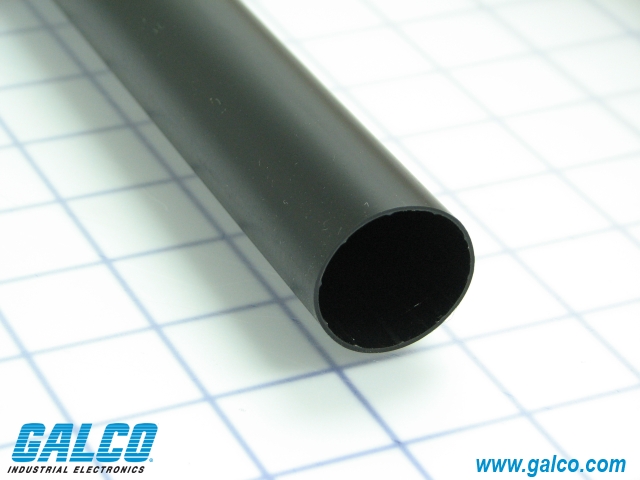

47-400124-BKNTE Electronics Shrink Tubing, THICK WALL WITH ADHESIVE Series

47-400124-BKNTE Electronics Shrink Tubing, THICK WALL WITH ADHESIVE Series Item Number47-400124-BKMFG Item Number47-400124-BKSeriesTHICK WALL WITH ADHESIVEProduct DescriptionHEAT SHRINK, 0.47in.x48in., BLK, 3:1,Specifications

Item Number47-400124-BKMFG Item Number47-400124-BKSeriesTHICK WALL WITH ADHESIVEProduct DescriptionHEAT SHRINK, 0.47in.x48in., BLK, 3:1,SpecificationsSpecifications Nom. Inner Diameter (in) 1/2 " Piece Length (in) 48 " Color Black Number of Pieces 1 Recovered Diameter 0.118 " Recovered Wall Thickness 0.098 " Adhesive Lining Yes Recovery Temperature 230 °F Operating Temperature -40-248 °F Availability -

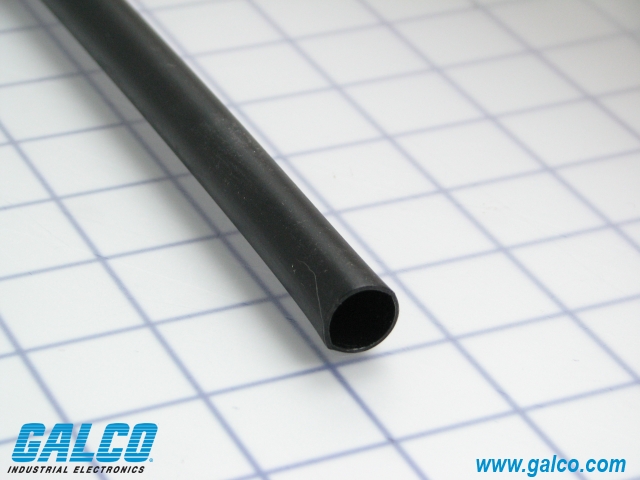

47-20248-BKNTE Electronics Shrink Tubing, THIN WALL Series

47-20248-BKNTE Electronics Shrink Tubing, THIN WALL Series Item Number47-20248-BKMFG Item Number47-20248-BKSeriesTHIN WALLProduct DescriptionHeat Shrink, 3/32in.x48in., Black, 2:1,Specifications

Item Number47-20248-BKMFG Item Number47-20248-BKSeriesTHIN WALLProduct DescriptionHeat Shrink, 3/32in.x48in., Black, 2:1,SpecificationsSpecifications Nom. Inner Diameter (in) 3/32 " Piece Length (in) 48 " Color Black Number of Pieces 1 Recovered Diameter 0.047 " Recovered Wall Thickness 0.02 " Adhesive Lining No Recovery Temperature 194 °F Operating Temperature -67-275 °F Availability -

HS-ASST-5NTE Electronics Shrink Tubing, Thin Wall Assortments Series

HS-ASST-5NTE Electronics Shrink Tubing, Thin Wall Assortments Series Item NumberHS-ASST-5MFG Item NumberHS-ASST-5SeriesThin Wall AssortmentsProduct DescriptionHEAT SHRINK ASST, 1/8in.x6in., ASSORTEDSpecifications

Item NumberHS-ASST-5MFG Item NumberHS-ASST-5SeriesThin Wall AssortmentsProduct DescriptionHEAT SHRINK ASST, 1/8in.x6in., ASSORTEDSpecificationsSpecifications Nom. Inner Diameter (in) 1/8 Length (In) 6 " Color(s) Black, Blue, Clear, Green, Red, White, Yellow Number of Pieces 10 Adhesive Lining No Recovery Temperature 200 °F Operating Temperature -67-275 °F Availability -

HS-ASST-2NTE Electronics Shrink Tubing, Thin Wall Assortments Series

HS-ASST-2NTE Electronics Shrink Tubing, Thin Wall Assortments Series Item NumberHS-ASST-2MFG Item NumberHS-ASST-2SeriesThin Wall AssortmentsProduct DescriptionHEAT SHRINK ASST, 2-1/2in., BLK,Specifications

Item NumberHS-ASST-2MFG Item NumberHS-ASST-2SeriesThin Wall AssortmentsProduct DescriptionHEAT SHRINK ASST, 2-1/2in., BLK,SpecificationsSpecifications Length (In) 2.5 " Color(s) Black Number of Pieces 158 Adhesive Lining No Recovery Temperature 200 °F Operating Temperature -67-275 °F Availability -

HSTT38-QPanduit Shrink Tubing, HSTT Series

HSTT38-QPanduit Shrink Tubing, HSTT Series Item NumberHSTT38-QMFG Item NumberHSTT38-QSeriesHSTTProduct DescriptionDry-Shrink HSTT38-Q Heat ShrinkSpecifications

Item NumberHSTT38-QMFG Item NumberHSTT38-QSeriesHSTTProduct DescriptionDry-Shrink HSTT38-Q Heat ShrinkSpecificationsSpecifications Nom. Inner Diameter (in) 1/5 " Roll Length (ft) 25 ' Color Black Number of Pieces 1 Recovered Diameter 0.187 " Recovered Wall Thickness 0.025 " Adhesive Lining No Operating Temperature -67-275 °F Availability -

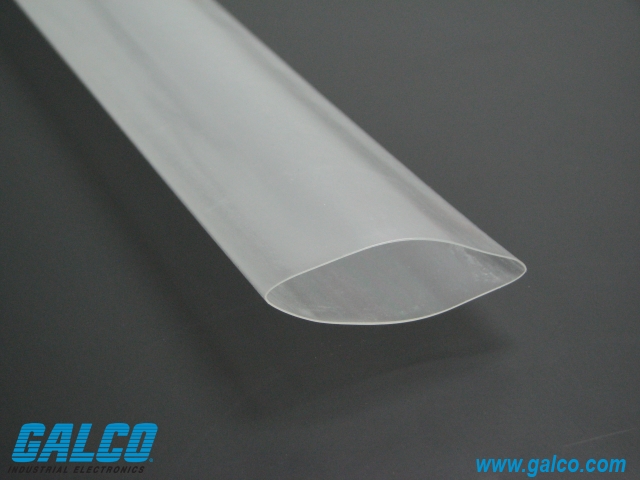

47-21148-CLNTE Electronics Shrink Tubing, THIN WALL Series

47-21148-CLNTE Electronics Shrink Tubing, THIN WALL Series Item Number47-21148-CLMFG Item Number47-21148-CLSeriesTHIN WALLProduct DescriptionHeat Shrink, 1-1/2in.x48in., Clear, 2:1,Specifications

Item Number47-21148-CLMFG Item Number47-21148-CLSeriesTHIN WALLProduct DescriptionHeat Shrink, 1-1/2in.x48in., Clear, 2:1,SpecificationsSpecifications Nom. Inner Diameter (in) 1-1/2 " Piece Length (in) 48 " Color Clear Number of Pieces 1 Recovered Diameter 0.752 " Recovered Wall Thickness 0.075 " Adhesive Lining No Recovery Temperature 194 °F Operating Temperature -67-275 °F Availability -

47-300278-BKNTE Electronics Shrink Tubing, MEDIUM WALL WITH ADHESIVE Series

47-300278-BKNTE Electronics Shrink Tubing, MEDIUM WALL WITH ADHESIVE Series Item Number47-300278-BKMFG Item Number47-300278-BKSeriesMEDIUM WALL WITH ADHESIVEProduct DescriptionHEAT SHRINK, 1.06in.x48in., BLK, 3.37:1,Specifications

Item Number47-300278-BKMFG Item Number47-300278-BKSeriesMEDIUM WALL WITH ADHESIVEProduct DescriptionHEAT SHRINK, 1.06in.x48in., BLK, 3.37:1,SpecificationsSpecifications Nom. Inner Diameter (in) 1 " Piece Length (in) 48 " Color Black Number of Pieces 1 Recovered Diameter 0.315 " Recovered Wall Thickness 0.098 " Adhesive Lining Yes Recovery Temperature 230 °F Operating Temperature -40-248 °F Availability -

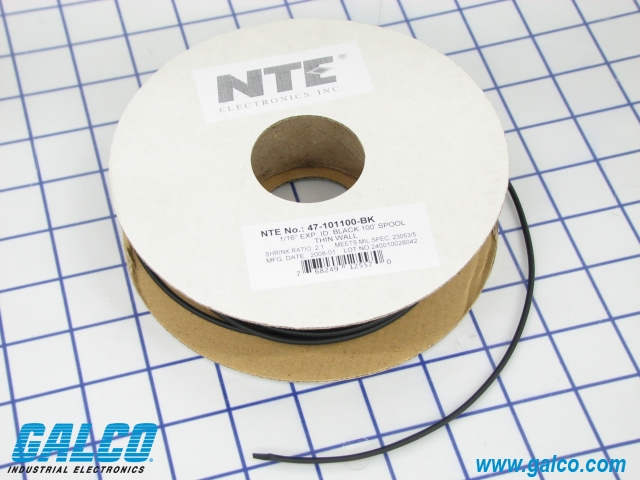

47-101100-BKNTE Electronics Shrink Tubing, THIN WALL Series

47-101100-BKNTE Electronics Shrink Tubing, THIN WALL Series Item Number47-101100-BKMFG Item Number47-101100-BKSeriesTHIN WALLProduct DescriptionHEAT SHRINK, 1/16in.x100ft., BLK, 2:1,Specifications

Item Number47-101100-BKMFG Item Number47-101100-BKSeriesTHIN WALLProduct DescriptionHEAT SHRINK, 1/16in.x100ft., BLK, 2:1,SpecificationsSpecifications Nom. Inner Diameter (in) 1/16 " Roll Length (ft) 100 ' Color Black Number of Pieces 1 Recovered Diameter 0.031 " Recovered Wall Thickness 0.017 " Adhesive Lining No Recovery Temperature 194 °F Operating Temperature -67-275 °F Availability -

47-23348-BKNTE Electronics Shrink Tubing, DUAL WALL WITH ADHESIVE Series

47-23348-BKNTE Electronics Shrink Tubing, DUAL WALL WITH ADHESIVE Series Item Number47-23348-BKMFG Item Number47-23348-BKSeriesDUAL WALL WITH ADHESIVEProduct DescriptionHEAT SHRINK, 3/8in.x48in., BLK, 3:1,Specifications

Item Number47-23348-BKMFG Item Number47-23348-BKSeriesDUAL WALL WITH ADHESIVEProduct DescriptionHEAT SHRINK, 3/8in.x48in., BLK, 3:1,SpecificationsSpecifications Nom. Inner Diameter (in) 3/8 " Piece Length (in) 48 " Color Black Number of Pieces 1 Recovered Diameter 0.118 " Recovered Wall Thickness 0.024 " Adhesive Lining Yes Recovery Temperature 230 °F Operating Temperature -67-185 °F Availability

Search

Shrink Tubing

Shrink tubing, or heat-shrink tubing, is a shrinkable plastic tube used to insulate wires. Shrink tubing protects wires from abrasion and other damage, and provides environmental sealing for stranded and solid wire, conductors, connections, and terminals.

Shrink tubing is ordinarily made of nylon, which shrinks radially and not longitudinally when heated. This reduces the tube&pos;s diameter without affecting the overall length of the tube. The nylon can be treated with chemical additives, and manufactured thicker or thinner, to meet the requirements for most environment demands.

Shrink tubing is fitted to wires and slid over connections before shrinking. Using this method, shrink tubing can be used to repair insulation, bundles wires together, and seal connections. It is available in a wide variety of colors to aid with cable management, and some designs may include adhesive on the inside of the tube to provide a better seal.

Shrink tubing is ordinarily made of nylon, which shrinks radially and not longitudinally when heated. This reduces the tube&pos;s diameter without affecting the overall length of the tube. The nylon can be treated with chemical additives, and manufactured thicker or thinner, to meet the requirements for most environment demands.

Shrink tubing is fitted to wires and slid over connections before shrinking. Using this method, shrink tubing can be used to repair insulation, bundles wires together, and seal connections. It is available in a wide variety of colors to aid with cable management, and some designs may include adhesive on the inside of the tube to provide a better seal.