-

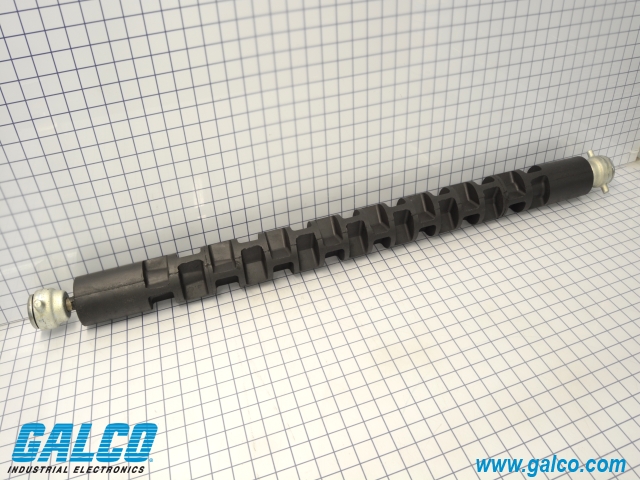

500984-308Joy Limberoller by Crouse-Hinds Conveyor Idlers, LR-350 SeriesItem Number500984-308MFG Item Number500984-308SeriesLR-350Product DescriptionTroughing Idler, LR-350, For 18in. Belt,Specifications

500984-308Joy Limberoller by Crouse-Hinds Conveyor Idlers, LR-350 SeriesItem Number500984-308MFG Item Number500984-308SeriesLR-350Product DescriptionTroughing Idler, LR-350, For 18in. Belt,SpecificationsSpecifications Bearing Type Tapered Toller Bearings Roll Diameter (in) 3 " Approx. Weight (lb) 8.5 lbs Mounting Length (in) 25.94 " Rubber Length (in) 21 " AvailabilityOrder by 5:00 PM ET and your package will ship the same day. -

500984-338Joy Limberoller by Crouse-Hinds Conveyor Idlers, LR-350 SeriesItem Number500984-338MFG Item Number500984-338SeriesLR-350Product DescriptionTroughing Idler, LR-350, For 36in. Belt,Specifications

500984-338Joy Limberoller by Crouse-Hinds Conveyor Idlers, LR-350 SeriesItem Number500984-338MFG Item Number500984-338SeriesLR-350Product DescriptionTroughing Idler, LR-350, For 36in. Belt,SpecificationsSpecifications Bearing Type Tapered Toller Bearings Roll Diameter (in) 3 " Approx. Weight (lb) 12 lbs Mounting Length (in) 43.13 " Rubber Length (in) 39 " AvailabilityOrder by 5:00 PM ET and your package will ship the same day. -

500984-315Joy Limberoller by Crouse-Hinds Conveyor Idlers, LR-350 SeriesItem Number500984-315MFG Item Number500984-315SeriesLR-350Product DescriptionTroughing Idler, LR-350, For 24in. Belt,Specifications

500984-315Joy Limberoller by Crouse-Hinds Conveyor Idlers, LR-350 SeriesItem Number500984-315MFG Item Number500984-315SeriesLR-350Product DescriptionTroughing Idler, LR-350, For 24in. Belt,SpecificationsSpecifications Bearing Type Tapered Toller Bearings Roll Diameter (in) 3 " Approx. Weight (lb) 10 lbs Mounting Length (in) 31.94 " Rubber Length (in) 27 " AvailabilityOrder by 5:00 PM ET and your package will ship the same day. -

1500409Joy Limberoller by Crouse-Hind Conveyor Idlers, Hanger SeriesItem Number1500409MFG Item Number1500409SeriesHangerProduct DescriptionReturn Hanger Bracket, For LR-106 &AvailabilityOrder by 5:00 PM ET and your package will ship the same day.

1500409Joy Limberoller by Crouse-Hind Conveyor Idlers, Hanger SeriesItem Number1500409MFG Item Number1500409SeriesHangerProduct DescriptionReturn Hanger Bracket, For LR-106 &AvailabilityOrder by 5:00 PM ET and your package will ship the same day. -

3500164Joy Limberoller by Crouse-Hinds Conveyor IdlersItem Number3500164MFG Item Number3500164Product DescriptionReturn Hanger Bracket, LR-307, HeavyAvailabilityOrder by 5:00 PM ET and your package will ship the same day.

3500164Joy Limberoller by Crouse-Hinds Conveyor IdlersItem Number3500164MFG Item Number3500164Product DescriptionReturn Hanger Bracket, LR-307, HeavyAvailabilityOrder by 5:00 PM ET and your package will ship the same day. -

377297Joy Limberoller by Crouse-Hinds Conveyor IdlersItem Number377297MFG Item Number377297Product DescriptionBEARING HOOK (2 REQft.D)AvailabilityOrder by 5:00 PM ET and your package will ship the same day.

377297Joy Limberoller by Crouse-Hinds Conveyor IdlersItem Number377297MFG Item Number377297Product DescriptionBEARING HOOK (2 REQft.D)AvailabilityOrder by 5:00 PM ET and your package will ship the same day. -

377996-1Joy Limberoller by Crouse-Hinds Conveyor IdlersItem Number377996-1MFG Item Number377996-1Product DescriptionRETURN HANGER FOR LR350 (2 REQft.D)AvailabilityOrder by 5:00 PM ET and your package will ship the same day.

377996-1Joy Limberoller by Crouse-Hinds Conveyor IdlersItem Number377996-1MFG Item Number377996-1Product DescriptionRETURN HANGER FOR LR350 (2 REQft.D)AvailabilityOrder by 5:00 PM ET and your package will ship the same day. -

378725-1Joy Limberoller by Crouse-Hinds Conveyor IdlersItem Number378725-1MFG Item Number378725-1Product DescriptionBracket, Top Mount, LR-106 & LR-107,AvailabilityOrder by 5:00 PM ET and your package will ship the same day.

378725-1Joy Limberoller by Crouse-Hinds Conveyor IdlersItem Number378725-1MFG Item Number378725-1Product DescriptionBracket, Top Mount, LR-106 & LR-107,AvailabilityOrder by 5:00 PM ET and your package will ship the same day. -

378725-2Joy Limberoller by Crouse-Hinds Conveyor IdlersItem Number378725-2MFG Item Number378725-2Product DescriptionBracket, Top Mount, LR-106 & LR-107,AvailabilityOrder by 5:00 PM ET and your package will ship the same day.

378725-2Joy Limberoller by Crouse-Hinds Conveyor IdlersItem Number378725-2MFG Item Number378725-2Product DescriptionBracket, Top Mount, LR-106 & LR-107,AvailabilityOrder by 5:00 PM ET and your package will ship the same day. -

378725Joy Limberoller by Crouse-Hinds Conveyor IdlersItem Number378725MFG Item Number378725Product DescriptionBracket, Top Mount, LR-106 & LR-107,AvailabilityOrder by 5:00 PM ET and your package will ship the same day.

378725Joy Limberoller by Crouse-Hinds Conveyor IdlersItem Number378725MFG Item Number378725Product DescriptionBracket, Top Mount, LR-106 & LR-107,AvailabilityOrder by 5:00 PM ET and your package will ship the same day.

Search

Conveyor Idlers

Conveyor idlers, or rollers, allow conveyor belts to bear more weight and move freely along their path. Rollers prop up the belt and rotate with the conveyor, preventing the belt from sagging under the load.

Conveyor idlers, supported by brackets to belt height, are typically placed side by side along the entire length of the belt. This facilitates free movement of the belt without impeding the transport of the load.

Conveyor idlers are outfitted with a tapered roller or double row ball bearings. Sealed bearings are common, although regreasable bearings are available should the idler wear down over time. Idlers vary by length, diameter, and type to match the width of the conveyor belt, the speed of the system, and the load they are designed to bear.

Conveyor idlers, supported by brackets to belt height, are typically placed side by side along the entire length of the belt. This facilitates free movement of the belt without impeding the transport of the load.

Conveyor idlers are outfitted with a tapered roller or double row ball bearings. Sealed bearings are common, although regreasable bearings are available should the idler wear down over time. Idlers vary by length, diameter, and type to match the width of the conveyor belt, the speed of the system, and the load they are designed to bear.